The group is a young and dynamic team with modern facilities to carry out a wide variety of experimental and computational studies. The high qualification of this group, backed by its extensive curriculum in teaching and research in many different fields of Fluid Mechanics, facilitates collaboration with any organisation that needs its services.

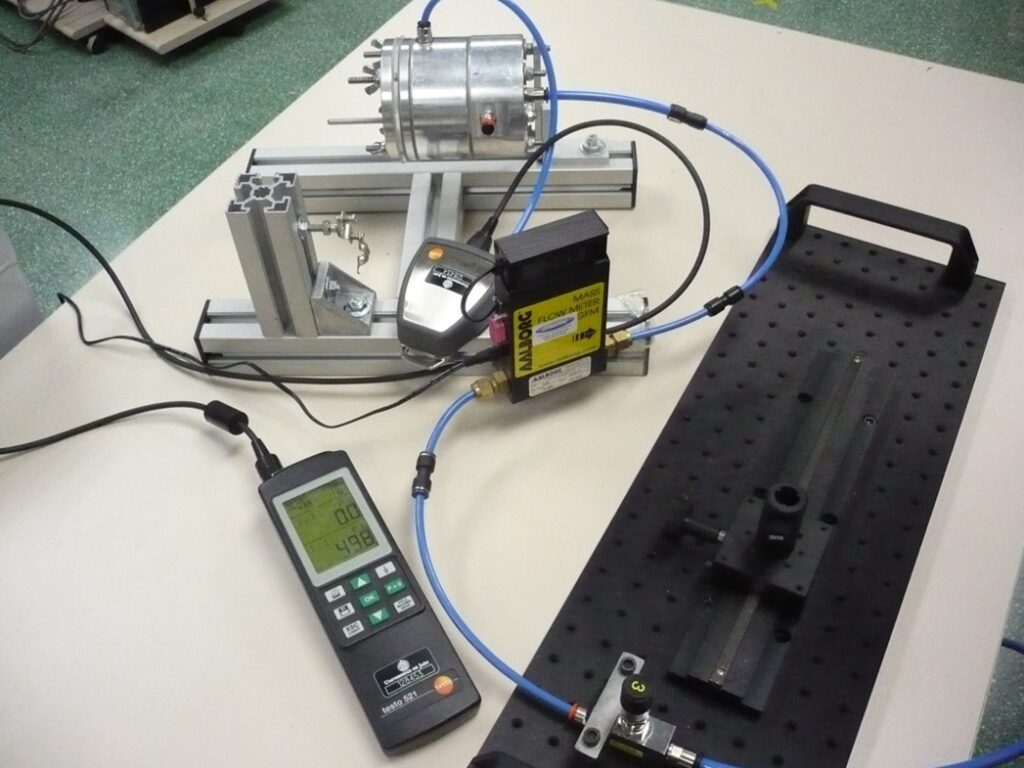

Our group has several laboratories equipped with state-of-the-art instrumentation and experimental facilities:

- Wind tunnels and hydrodynamic channels for flow characterisation around models.

- Laser (LDV, PIV) and thermal anemometry equipment. For temporal and spatial characterisation of fluxes.

- High-speed imaging equipment: cameras, lenses, lighting, etc.

- Pressure sensors (water and multi-channel air), flow meters, precision thermometers, etc.

For numerical studies we have several clusters (supercomputers) for parallel computing and workstations that allow us to perform a wide variety of computational calculations, data post-processing and visualisation of results.

Therefore, we can offer services for the characterisation of any industrial flow or problem by means of experiments, numerical simulations and theoretical analysis. Among others:

- Aerodynamic studies of models.

- Analysis of wind loads or flow-induced vibrations.

- Simulation of flows in plastic injection moulding systems.

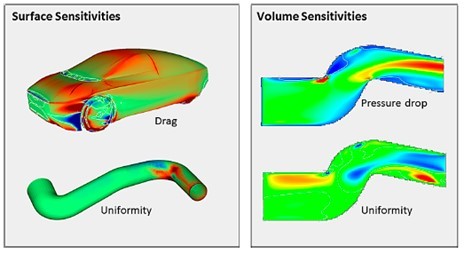

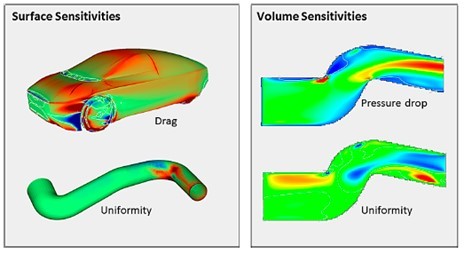

- Optimised design of fluid-thermal or aerodynamic systems using shape optimisation tools.

- Cooling study of solar panels, heat exchangers or radiators.

- Characterisation of air-conditioning, ventilation or refrigeration systems.

- Design of air injection systems in liquids.

- Analysis and design of water saving systems.

- Fire spread simulations.

- Characterisation of ducts and networks.

- Consultancy and technical advice.

- Manufacture of parts and prototypes.

Our group offers training courses in the field of applied fluid mechanics for companies and professionals. Among the courses offered are the following:

- Computational Fluid Mechanics (CFD)

- Experimental measurement techniques (laser velocimetry, particle image velocimetry, hot-wire anemometry, etc.)

- High-speed image acquisition and processing.

- Design of distribution networks and pumping systems.

- Numerical simulation and experimental characterisation of processes in the plastics industry.